In the realm of construction projects, the significance of underground ducting cannot be overstated. This vital component serves as the backbone for efficiently routing essential utilities such as electrical, communication, and ventilation systems beneath the surface. As highlighted by industry expert Dr. Emily Carter, a leading figure in civil engineering, “Underground ducting is not just about functionality; it’s about creating a sustainable future by minimizing visual clutter and enhancing infrastructure resilience.”

Underground ducting plays a crucial role in ensuring that urban landscapes remain both aesthetically pleasing and operationally effective. By concealing vital utilities underground, construction projects can maximize space above ground for greenery, pedestrian pathways, and other essential features. Furthermore, this method of installation reduces the risk of damage from environmental factors and human activity, thereby extending the lifespan of utility systems and enhancing overall safety.

In this article, we will explore the intricacies of underground ducting, including its design principles, installation processes, and the technological advancements that are shaping its future. By understanding the importance and functionality of underground ducting, stakeholders in construction projects can make informed decisions that contribute to the sustainability and resilience of our built environment.

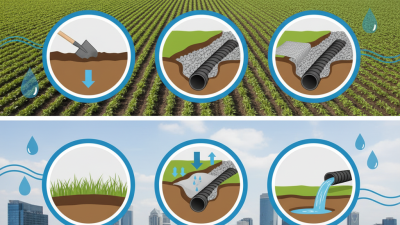

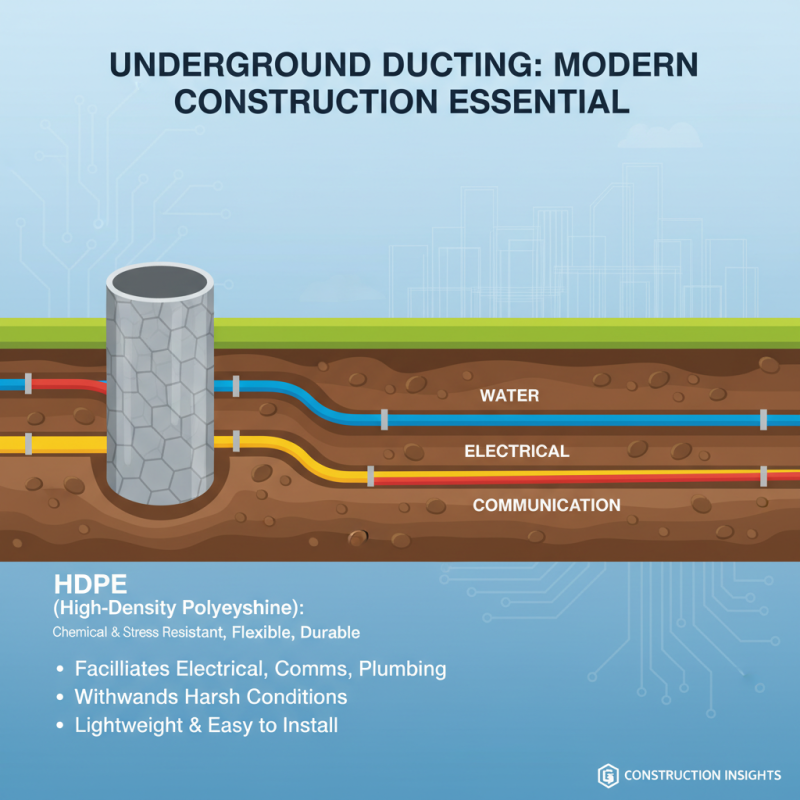

Underground ducting is a crucial element in construction projects, facilitating the safe and efficient transportation of utilities such as electrical wiring, telecommunications cables, and plumbing systems beneath the ground. This system involves pre-installed channels or tubes that protect these utilities from environmental conditions and physical damage while providing a clear pathway for installation and maintenance. The use of underground ducting helps to optimize the layout of infrastructure in urban areas, minimizing surface disruption and maintaining aesthetic appeal.

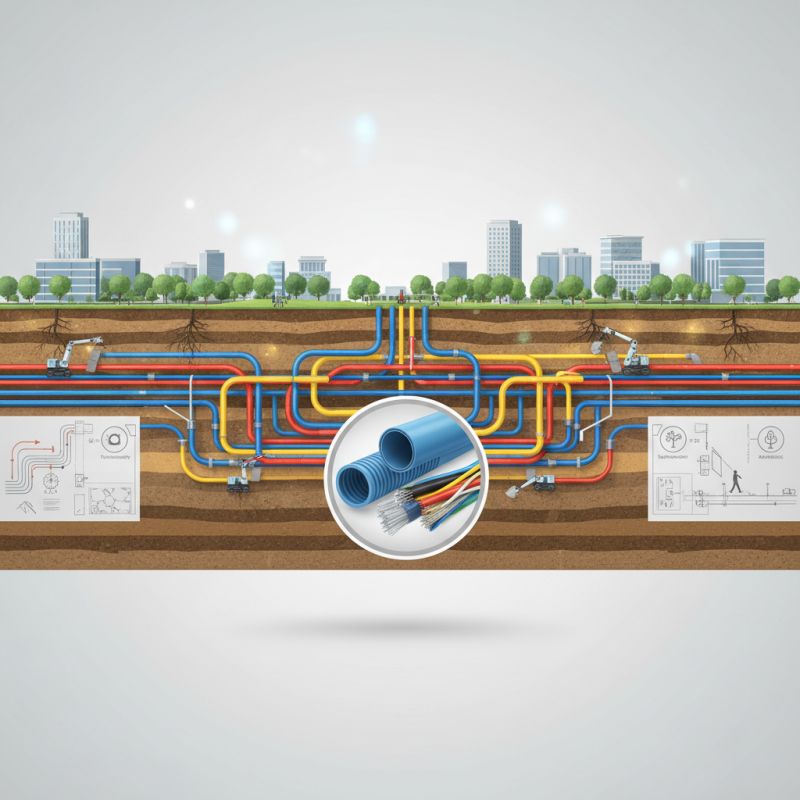

In construction projects, underground ducting is typically designed to endure various external pressures and environmental factors. The ducts can be made from materials such as PVC, HDPE, or concrete, each selected based on the specific requirements of the project and local soil conditions. Proper installation of underground ducting is essential, as it must comply with building codes and regulations to ensure safety and functionality. Effective planning and design can streamline future maintenance efforts, allowing for easier access to utilities without the need for disruptive excavation work.

This chart illustrates the percentage of different types of underground ducting used in construction projects. PVC ducts are the most commonly used, accounting for 60%, followed by concrete ducts at 25%, metal ducts at 10%, and fiber ducts at 5%.

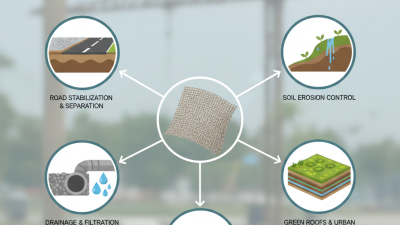

Underground ducting systems play a crucial role in modern construction projects, providing essential pathways for the transportation of air, electrical cables, and other utilities. These systems primarily consist of several key components, which include ductwork, access points, insulation, and sealing materials. Ductwork, often made from robust materials such as PVC or metal, forms the backbone of the entire system, designed to withstand environmental pressures while ensuring efficient flow and minimal energy loss. According to a recent industry report by the Building Research Establishment, proper ductwork installation can lead to up to a 30% decrease in energy consumption for heating and cooling in commercial buildings.

Access points are critical for maintaining and servicing the underground ducting system. These strategically placed openings allow technicians to perform inspections and repairs without major disruptions to the overall structure. Insulation is another vital component, as it minimizes heat exchange between the duct and the surrounding soil, thereby enhancing system efficiency. A 2022 study from the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) reveals that well-insulated duct systems can improve thermal efficiency ratings by as much as 25%. Finally, using sealing materials ensures that air leakage is kept to a minimum, further promoting the system’s overall performance. These components work together to create an integrated solution, essential for the successful operation of underground ducting systems in construction projects.

Underground ducting plays a vital role in modern construction projects, especially when it comes to the facilitation of electrical, communication, and plumbing systems. Various materials are utilized in these applications to ensure durability and effectiveness. One of the most commonly used materials is high-density polyethylene (HDPE), known for its excellent resistance to chemicals and environmental stress. HDPE ducts are lightweight, flexible, and can withstand harsh conditions, making them ideal for underground installations.

Another popular choice is reinforced concrete, which provides robust structural support and longevity. It is particularly suitable for heavy-duty applications where soil pressure and external loads are significant concerns. Additionally, PVC (polyvinyl chloride) is often employed for its corrosion resistance and ease of installation. PVC ducts are typically used for electrical conduits and ventilation systems due to their lightweight nature and cost-effectiveness. Each material brings unique advantages to underground ducting, enabling construction projects to meet specific needs and code requirements efficiently.

When it comes to underground ducting in construction projects, installation techniques play a crucial role in ensuring the system's efficiency and longevity. One of the most essential practices during installation is proper excavation. Careful planning and soil testing should be conducted prior to digging to prevent unexpected complications, such as encountering rock or water sources. Additionally, ensuring that trenches are deep and wide enough to accommodate the ducts while allowing for adequate backfill is vital.

**Tips:** Always check local building codes and regulations to confirm that your trench dimensions meet the necessary requirements. This can save you from costly adjustments later on.

Once the trench is ready, the ducting materials should be placed on a stable foundation to avoid sagging or damage under pressure. It's recommended to use a sand or gravel base to provide drainage and support. After positioning the ducts, secure them properly and ensure that there are adequate seals where necessary to prevent infiltration from moisture. Avoid bending the ducts sharply, as this can restrict airflow and lead to performance issues.

**Tips:** Consider marking the location of ducting with visible markers for future maintenance and inspection. This proactive measure can help avoid accidental damage from subsequent underground activities.

Underground ducting is increasingly recognized as a vital component in urban development projects, mainly for its ability to streamline infrastructure while enhancing urban aesthetics. According to a report by the American Society of Civil Engineers, the efficiency of underground utilities can lead to a reduction in surface disruption by up to 40%, which is particularly beneficial in densely populated areas. This efficiency not only facilitates smoother traffic flow and easier pedestrian access but also minimizes the environmental impact often associated with surface-level installations.

Furthermore, using underground ducting systems can significantly improve the longevity and maintenance of urban infrastructure. The National Institute of Standards and Technology indicates that buried utility lines have a lifespan that can exceed 50 years, compared to just 20-30 years for overhead lines. This durability is particularly advantageous for cities facing increasing demands for reliable and resilient infrastructure. Additionally, underground ducting systems can effectively decrease maintenance costs by protecting essential services such as electrical, telecommunications, and water lines from weather-related damage, thus ensuring uninterrupted service to urban residents and businesses alike.