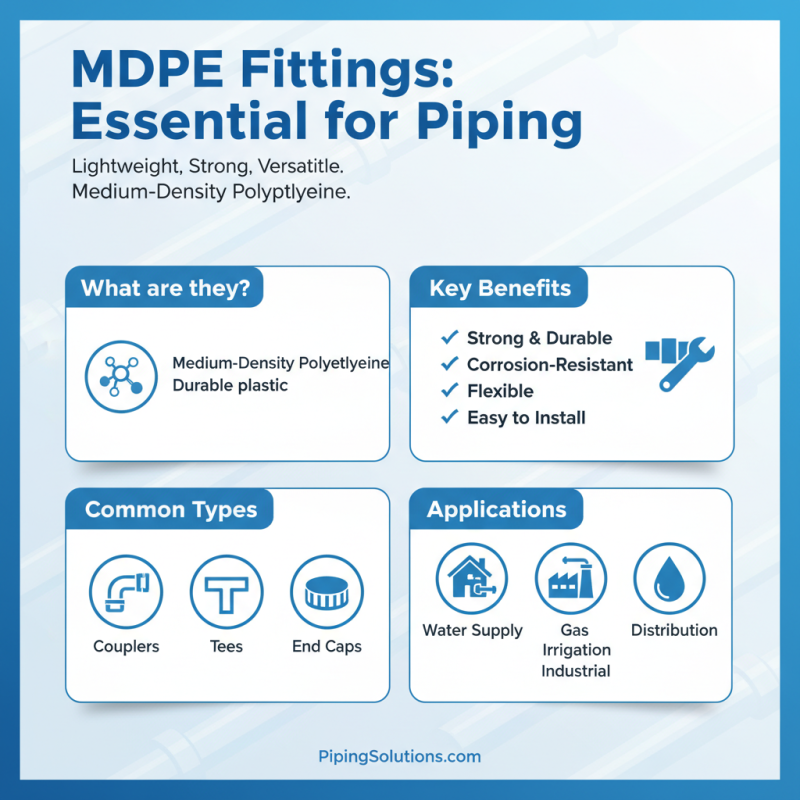

When embarking on projects that require durable plumbing solutions, understanding mdpe fittings is essential. MDPE, or Medium-Density Polyethylene, offers durability and flexibility. These fittings play a significant role in connecting pipes securely. They resist corrosion and withstand high pressure. This versatility is invaluable in both domestic and industrial applications.

Selecting the right mdpe fittings can be daunting. Many options exist, each with unique features. You may wonder which fittings work best for your specific needs. Mistakes in choosing fittings can lead to leaks or failures. It’s crucial to consider the environment and pressure levels when making selections.

This article highlights the top 10 mdpe fittings you should know about. Each fitting is discussed in detail, with its advantages and ideal applications explained. As you explore these options, think about their impact on your projects. Make informed decisions, and reflect on your choices. The right fitting can make all the difference.

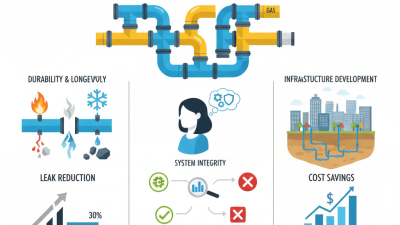

MDPE, or Medium-Density Polyethylene, is a type of thermoplastic polymer. It is widely used in construction projects due to its unique properties. MDPE offers excellent durability and resistance to corrosion. This makes it suitable for various applications, including water supply and gas distribution. Additionally, MDPE fittings are designed to connect piping systems securely and effectively.

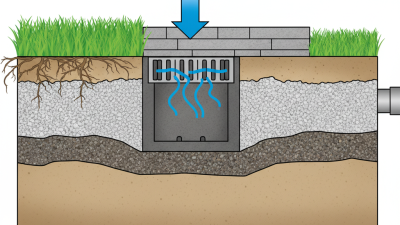

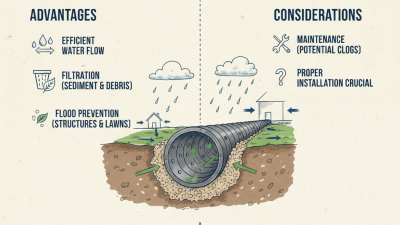

In construction, flexibility is crucial. MDPE fittings provide that. They adapt to different terrains and conditions. Workers can easily install these fittings without specialized tools. However, improper installation can lead to leaks. It's important to follow guidelines closely. Also, choosing the right type of fitting for specific applications is essential for long-term performance.

Moreover, MDPE fittings come in various shapes and sizes. These options allow for versatile design in projects. Still, not all designs may suit every need. Some may struggle with extreme weather conditions. Therefore, proper evaluation before usage is necessary. Understanding the limitations of MDPE is crucial for successful application.

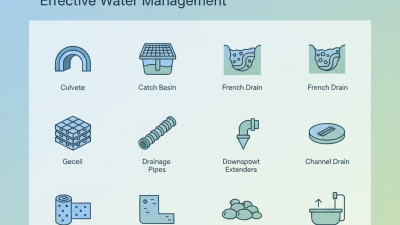

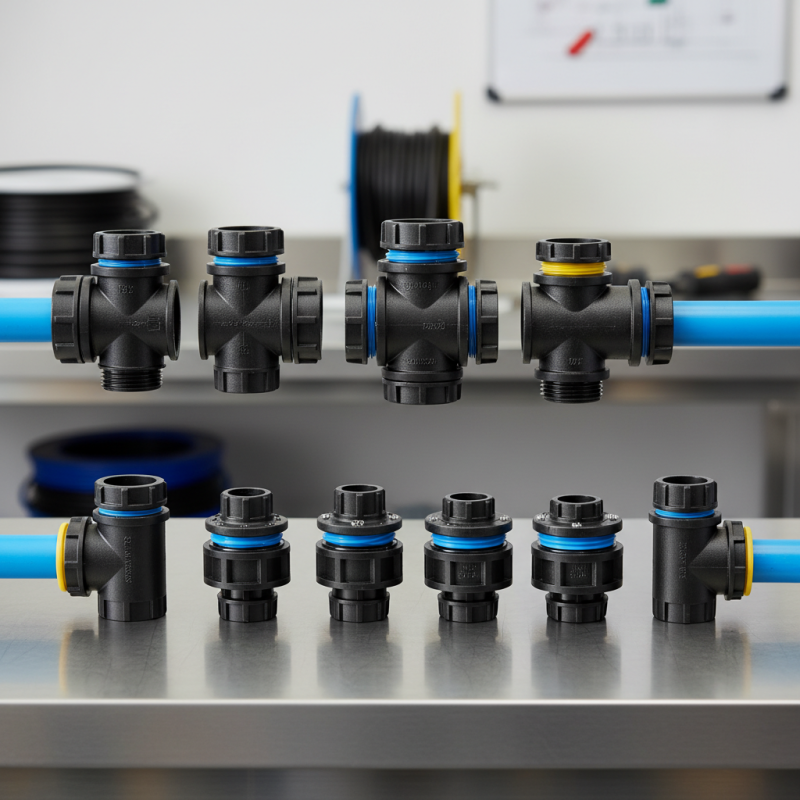

MDPE fittings are crucial for anyone involved in piping projects. These fittings are made from medium-density polyethylene. They are lightweight yet strong, making them ideal for various applications. You'll encounter different types, each serving unique purposes.

One of the most common fits is the elbow. It easily connects two pipes at an angle. This is vital for bending the piping system. Then there are tees, which split a single line into two. They can be handy for branching out your system efficiently. Couplings also play a key role. These connect two pipe ends securely.

However, sourcing the right MDPE fittings requires careful thought. Not all fittings are created equal. Some may not hold up under pressure. Secondly, the installation process isn’t always straightforward. It often requires careful alignment. Even small errors can lead to leaks later. Ultimately, knowing these basics will make your project smoother.

When selecting MDPE fittings for projects, specific features play a crucial role. The material's density is essential. High-density polyethylene offers durability and resistance to various chemicals. This makes it suitable for many applications. Consider the pressure rating of the fittings. It should match your project’s requirements. Underestimating this can lead to leaks or failures.

The size and compatibility of fittings matter, too. Ensure the fitting size corresponds with the pipe diameter. Misalignment can cause significant issues. Look for easy installation features. Fittings that require minimal tools save time and effort. This is especially helpful for large projects.

Don’t overlook the climate resistance of the material. MDPE fittings should withstand UV rays and extreme temperatures. Check if they retain integrity under stress. Cost is another factor. Quality fittings might cost more upfront but can prevent costly repairs. Evaluating these features leads to better choices, enhancing overall project success.

When working with MDPE fittings, proper installation is crucial for ensuring system integrity. Common methods, such as fusion welding, are highly effective. This technique creates a leak-free joint by melting the materials together. According to a report by the American Society of Plumbing Engineers, correctly installed MDPE can reduce leakage rates significantly, often to less than 1%.

Another popular method involves mechanical fittings, which can save time and labor. These fittings are designed for straightforward assembly, relying on a mechanical grip rather than heat. However, improper tightening can lead to failures. A study by the Plastics Pipe Institute reveals that nearly 15% of failure incidents stem from poor installation practices. It's essential to ensure that each fitting is inspected, especially in complex systems.

Moreover, it's critical to account for temperature variations. MDPE can expand and contract with temperature changes, potentially impacting joints. Using fittings rated for a broader temperature range may help mitigate issues. However, the industry still faces challenges. Tools and practices vary widely, leading to inconsistencies in quality. Regular training and updated guidelines could address these gaps in installation techniques.

MDPE fittings are crucial in various projects, especially in water supply and gas distribution. To ensure their longevity, proper maintenance is key. According to industry studies, routine inspections can significantly reduce failure rates, which are a common concern. In fact, 30% of failures in HDPE systems arise from joint issues. Keeping an eye on these connections helps maintain system integrity.

Regular cleaning prevents debris from accumulating. A simple cloth can work wonders. Do not use harsh chemicals that may damage the fittings. Instead, opt for gentle cleansers. Tightening loose fittings can also help avoid leaks. Many professionals overlook this simple step, but it makes a difference in performance.

Environmental factors like temperature fluctuations can affect MDPE fittings. A report by the International Plastic Pipe Association states that extreme temperatures can reduce the lifespan of these components by 20%. Insulation can mitigate such risks. Pay attention to installation guidelines; improper techniques are a common pitfall. Ensure fittings are not exposed to direct sunlight for prolonged periods.