In the quest for efficient water drainage and filtration, perforated pipes emerge as a critical solution for both residential and commercial applications. With their strategically designed holes, these pipes facilitate the seamless flow of water while preventing the entry of unwanted debris, making them an ideal choice for a variety of environments. The use of perforated pipe systems can significantly enhance the management of stormwater, sewage, and agricultural runoff, ensuring that water is effectively channeled away from structures and landscapes.

An efficient water drainage system is essential for maintaining not only the integrity of properties but also the health of surrounding ecosystems. Perforated pipes offer a reliable method for filtering water as it passes through, allowing for better absorption into the ground and reducing the risk of flooding. Furthermore, these systems can promote sustainability by recharging groundwater supplies and minimizing the impact of surface runoff on local water bodies.

As we delve deeper into the best perforated pipe solutions available, it is important to explore their various applications, benefits, and best practices for installation. Understanding the advantages of perforated pipes will enable homeowners, builders, and landowners to make informed decisions that enhance drainage efficiency and promote long-term environmental stewardship.

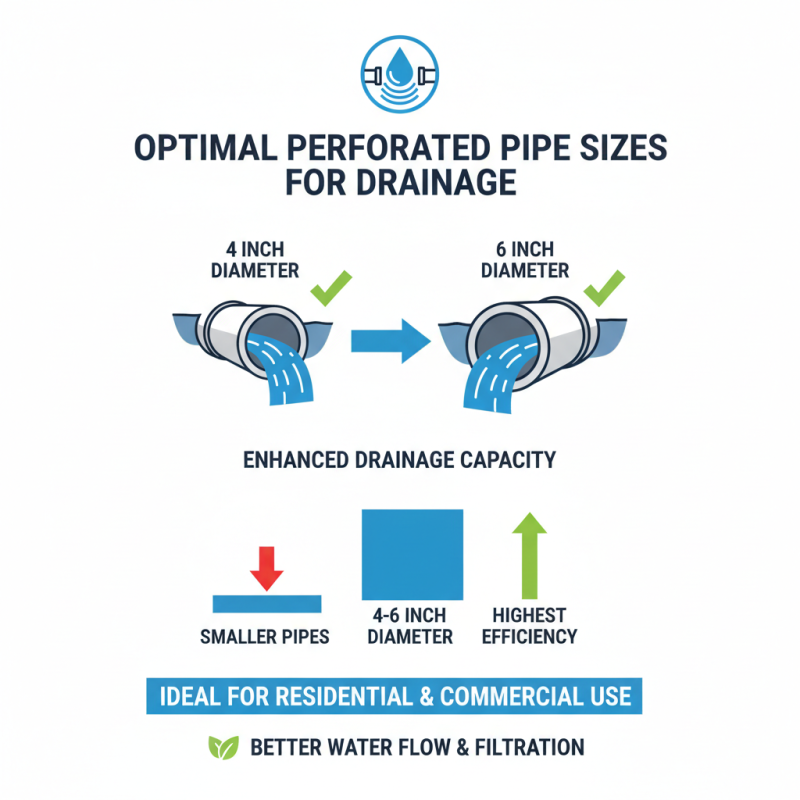

When selecting perforated pipe sizes for drainage systems, several key factors must be considered to ensure optimal water flow and filtration efficiency. According to industry reports, properly sized perforated pipes can significantly enhance drainage capacity. For instance, a study published by the American Society of Civil Engineers indicates that using perforated pipes with diameters of 4 to 6 inches can achieve the highest efficiency in handling stormwater runoff. This size range is ideal for most residential and commercial drainage applications, offering a balance between flow capacity and installation practicality.

In addition to diameter, the spacing and size of perforations play a crucial role in the performance of drainage systems. Research from the International Association of Plumbing and Mechanical Officials suggests that perforations should typically be spaced between 6 to 12 inches apart to maintain effective filtration while preventing clogging. The perforation size should also be chosen based on the expected sediment load; smaller openings may be necessary in areas with high silt content, while larger perforations may suffice in less contaminated environments. By adhering to these best practices, engineers can optimize the design of drainage systems, enhancing both their efficiency and longevity.

Perforated pipes play a crucial role in effective water drainage and filtration systems. The design of these pipes, particularly their perforation patterns, significantly influences the efficiency of water movement and the removal of particulates. Research conducted by the Water Environment Federation indicates that optimal perforation sizes and spacing can enhance flow rates while minimizing clogging, thus maintaining a consistent level of performance. For example, a study found that pipes with 1-inch holes spaced 12 inches apart yielded 30% better drainage efficiency compared to those with smaller, closer holes.

Moreover, the impact of perforation patterns extends to water filtration capabilities. Different configurations can affect the particles that can be filtered out and the overall retention time of water in the system. According to a report from the International Stormwater Best Management Practices (BMP) Database, systems utilizing strategically placed perforations can trap sediment and organic material more effectively, leading to higher water quality. It has been documented that perforated pipes with triangular or oval perforation patterns offered improved sediment capture rates, removing up to 50% more contaminants than traditional round patterns. As such, understanding and optimizing perforation designs is essential for both drainage and water filtration efficiency.

When choosing the right materials for perforated pipe manufacturing, it is essential to consider the specific application and environmental conditions. Common materials include PVC, HDPE, and metal, each offering distinct advantages. For instance, PVC is lightweight and resistant to corrosion, making it ideal for residential drainage systems. On the other hand, HDPE provides greater flexibility and durability, which is beneficial for challenging terrains or heavy-load situations. Metals, while more robust and long-lasting, can succumb to rust and corrosion if not adequately protected, making them suitable for specific industrial applications.

Tips: When selecting a perforated pipe, always consider the specific needs of your drainage or filtration system. Evaluate factors such as the chemical exposure, soil conditions, and intended use to choose the best material. Regular inspections can also help in identifying potential issues early, ensuring longevity and efficiency.

In addition, the design of the perforations is equally crucial. The size, pattern, and spacing of the holes can significantly impact water flow and filtration efficiency. A well-designed perforated pipe system allows for optimal drainage while preventing sediment build-up. Therefore, understanding the hydraulic demand and soil characteristics is essential for selecting the correct perforated pipe configuration for your project.

In the realm of efficient water drainage and filtration, the key performance metrics of flow rate and filtration efficiency play a crucial role in determining the effectiveness of perforated pipe solutions. According to a report by the American Society of Civil Engineers (ASCE), properly designed drainage systems can significantly reduce surface runoff, helping to mitigate flooding and promote water quality. A perforated pipe that achieves a flow rate of 15-30 gallons per minute per linear foot is often ideal for residential installations, ensuring that excess water is effectively managed while minimizing potential land erosion.

Filtration efficiency is another critical metric, particularly in applications where water quality is paramount. A study published in the Journal of Environmental Engineering highlights that perforated piping systems equipped with geotextile filters can achieve a filtration efficiency exceeding 95% for sediments, ensuring that the water being drained is free from harmful particles. This high level of efficiency not only protects local ecosystems from sedimentation but also enhances the longevity of drainage systems by reducing clogs and maintenance requirements. As such, selecting the right perforated pipe with optimal flow rate and filtration efficiency is essential for effective water management solutions in various applications.

| Pipe Diameter (inches) | Material | Flow Rate (GPM) | Filtration Efficiency (%) | Applications |

|---|---|---|---|---|

| 6 | PVC | 45 | 85 | Agricultural Drainage |

| 8 | HDPE | 75 | 90 | Stormwater Management |

| 10 | Concrete | 100 | 95 | High-Volume Runoff |

| 12 | Steel | 150 | 80 | Industrial Applications |

| 4 | Fiberglass | 30 | 75 | Residential Drainage |

To ensure the longevity of perforated pipe systems, effective maintenance strategies are critical. Regular inspection is a foundational step; according to the American Society of Civil Engineers, proper inspections can identify early signs of clogging, structural damage, or deterioration. It is recommended to conduct these checks at least twice a year, especially before and after heavy rainfall seasons. This proactive approach helps in detecting issues that could lead to significant water retention problems or soil erosion.

Another essential aspect of maintenance is cleaning techniques to mitigate sediment buildup within the pipes. A study by the Environmental Protection Agency highlights that routine flushing or hydro jetting can remove accumulated debris, thus facilitating optimal water flow and preventing blockages. Furthermore, utilizing geotextiles around the pipes can help filter out particles before they reach the perforated structure, significantly reducing maintenance needs over time. By implementing these strategies, the functionality and lifespan of perforated pipe systems can be greatly enhanced, ensuring efficient drainage and filtration.