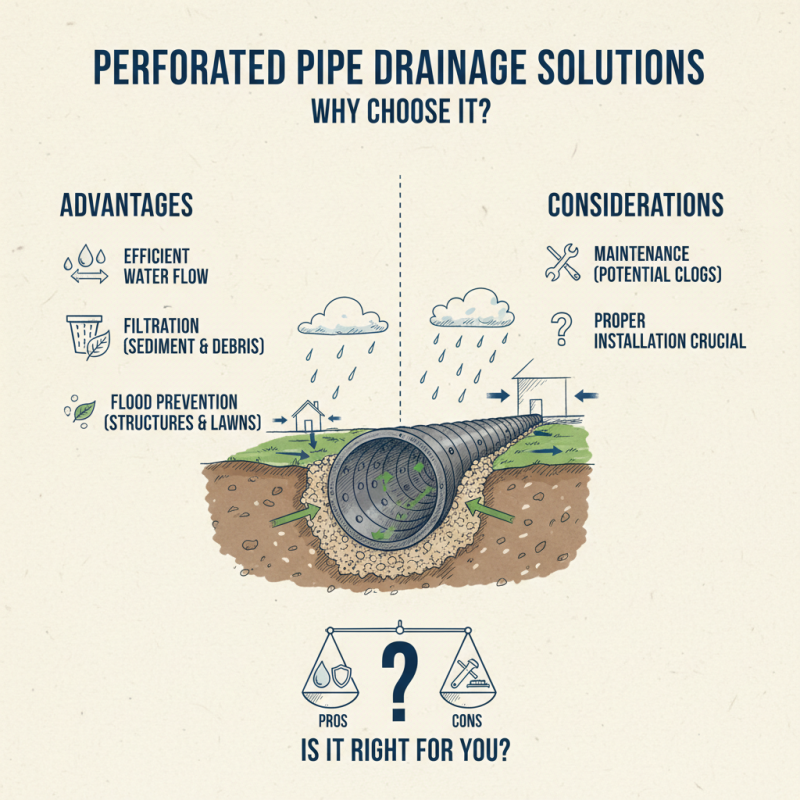

When considering drainage solutions, the choice of materials is crucial. One popular option is perforated pipe. This innovative solution offers numerous advantages for managing water flow effectively. With holes or slots along its length, the perforated pipe aids in efficient drainage.

The design allows water to enter while filtering out sediment and debris. This feature enhances the longevity of the drainage system. Imagine a heavy rainstorm, where water accumulates rapidly. A well-installed perforated pipe can prevent flooding by channeling excess water away from structures and lawns. However, not all installations are perfect. Some users report clogs over time, which require regular maintenance.

Choosing perforated pipe for drainage involves careful consideration. Improper installation can lead to problems. Yet, when done correctly, it provides a reliable solution for various drainage needs. It is essential to weigh the pros and cons. Is perforated pipe the best choice for your requirements?

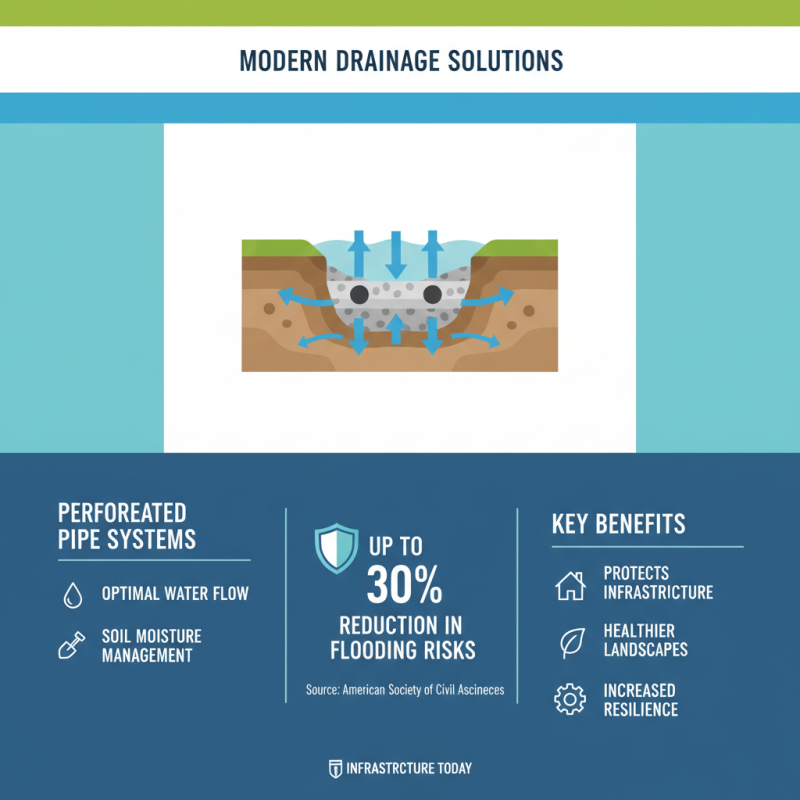

Perforated pipe systems are increasingly becoming the go-to choice for drainage solutions. These systems provide excellent water flow while managing soil saturation. According to the American Society of Civil Engineers, well-designed drainage systems can reduce flooding risks by up to 30%. This statistic highlights the critical role that perforated pipes play in modern infrastructure.

One major benefit of perforated pipes is their ability to filter and drain groundwater efficiently. The holes allow water to flow in while preventing soil and debris from blocking the system. Research indicates that perforated pipes can enhance soil drainage rates by 50% compared to solid pipes. This improvement can lead to healthier landscapes and better agricultural outcomes.

However, it's essential to recognize limitations. Over time, perforated pipes can become clogged due to fine particles. Regular maintenance is crucial but often overlooked. Some studies suggest that up to 40% of drainage failures result from a lack of maintenance. Understanding these challenges helps in planning for a sustainable drainage approach. Incorporating perforated pipes is beneficial, but it requires ongoing care to ensure longevity and efficiency.

When considering drainage solutions, perforated pipes can offer unique advantages. The pattern of holes in the pipe is crucial. Different perforation patterns can significantly impact flow rates. A pipe with uniformly spaced holes may allow for consistent water distribution, which can help in managing drainage effectively. Irregular patterns might create areas where water flow slows down, leading to potential pooling issues.

Tips: Think about the soil type. Sandy soil allows for faster drainage, while clay can slow it down. Match your perforation pattern to these conditions. This approach can optimize flow rates, preventing water accumulation.

Another point to ponder is the pipe's diameter. A larger diameter may seem better for flow, yet it could lead to sediment build-up over time. Smaller diameters with strategic perforations might lessen this risk. Keep in mind the maintenance required to keep the system efficient.

Tips: Regularly inspect your drainage system. Look for signs of clogging or slow drainage. Adjust your perforation design if issues arise. Reflection on your setup can lead to long-term benefits.

This bar chart illustrates the relationship between different perforation patterns in drainage pipes and their corresponding flow rates. As shown, various patterns affect the efficiency of water flow through the pipe.

When it comes to drainage systems, comparing perforated pipe and solid pipe highlights significant differences.

Perforated pipes feature holes along their length, allowing water to enter while filtering out soil and debris. This design increases drainage capacity, making them ideal for areas with high water tables or saturated soils. Reports show that perforated pipes can improve drainage by up to 60% compared to solid alternatives.

On the other hand, solid pipes prevent water from entering and are better suited for transporting water away from a site. However, solid pipes can create problems in areas prone to flooding or heavy rainfall. Research indicates that solid pipes may lead to water pooling, which can damage landscaping or infrastructure over time. The flexibility of perforated pipes allows them to adapt to varying drainage needs, while solid pipes can sometimes limit options for water management.

Choosing the right pipe for drainage is crucial. Factors like soil type, slope, and rainfall patterns all play a role. Perforated pipes seem beneficial in many scenarios, but their installation can be tricky. Improper placement may still result in inadequate drainage, which can be detrimental. Each installation must be carefully considered to avoid future complications.

Perforated pipe systems are increasingly recognized for their effectiveness in drainage solutions. They meet various industry standards, ensuring reliable performance. The material used often includes high-density polyethylene (HDPE) or PVC, both resistant to corrosion and chemicals. According to a report by the American Society for Testing and Materials, HDPE can withstand rough environmental conditions, extending its lifespan significantly.

Design considerations are crucial for optimal functionality. Size and perforation patterns should align with the specific drainage needs. For instance, a study by the Engineering Toolbox outlines that hole sizes typically range from 1/8 inch to 1 inch. This size range allows for sufficient water flow while preventing gravel infiltration. However, improper sizing can lead to clogs and inefficiencies.

Many projects overlook the importance of installation depth. Incorrect depth can result in poor drainage performance. A survey by the National Association of Home Builders indicates that improper installation accounts for up to 25% of drainage issues in residential areas. Choosing the right perforated pipe is vital in avoiding these common pitfalls. Attention to detail in both material selection and design will greatly improve drainage effectiveness.

| Parameter | Description | Material | Design Features |

|---|---|---|---|

| Perforation Size | The diameter of holes to optimize water flow | Polyvinyl Chloride (PVC) | Large perforations for rapid drainage |

| Pipe Diameter | The outer dimension of the pipe | High-Density Polyethylene (HDPE) | Available in various diameters (e.g., 4", 6", 8") |

| Length | Standard lengths for ease of installation | Concrete | Typically 10 or 20 feet sections |

| Drainage Capacity | Max water flow rate the pipe can handle | Galvanized Steel | Engineered for specific flow rates |

| Installation Method | Methods for placing pipes underground | Fiberglass | Trenching or horizontal boring |

Perforated pipes have become a go-to solution for effective drainage in various projects. One compelling case study involved a local sports field facing constant waterlogging. The team opted for perforated pipes buried in a gravel bed. This setup allowed excess rainwater to drain quickly, enhancing field usability. Unfortunately, the initial installation faced challenges due to incorrect pipe placement, but adjustments were made to ensure proper slope.

Another project showcased the use of perforated pipes in residential drainage systems. Homeowners grappled with basement flooding during heavy storms. As a solution, a system of perforated pipes was integrated around the foundation. This channeled water away effectively. However, some residents reported minor clogs over time, underscoring the need for regular maintenance. This highlights the potential requirement for ongoing care even after successful installation.

These examples reveal the versatility and effectiveness of perforated pipes in drainage. However, they also remind us that every project can experience hiccups. Addressing these challenges is vital for long-term success. Proper planning and ongoing maintenance can make a significant difference in utilizing perforated pipes effectively.