A corrugated drain pipe is a vital component in drainage systems. Its unique design allows for flexible installation, making it suitable for various applications. Often made from lightweight materials, the corrugated structure enables easy transportation and handling.

These pipes are commonly used in residential and commercial settings. They help manage stormwater runoff effectively, preventing flooding and soil erosion. However, they might not be ideal for every situation. The installation process can be tricky, requiring careful consideration of the terrain.

While a corrugated drain pipe offers many benefits, it is essential to evaluate its limitations. For instance, improper installation may lead to clogs or ineffective drainage. This highlights the necessity of proper planning and execution when using such pipes. Understanding their function and appropriate use can make a significant difference in drainage efficiency.

Corrugated drain pipes are widely used in drainage systems. Their unique structure allows for flexibility and strength. Made from durable materials, they are designed to withstand various environmental conditions. The pipe’s surface has ridges that enhance flow capacity, preventing blockages. This unique shape helps accommodate the natural movement of soil and water.

One interesting feature is their lightweight nature. This makes installation easier and more cost-effective. However, care must be taken during handling. If dropped, these pipes may get damaged. Additionally, improper installation can lead to serious issues later on. It can cause leaks or even collapse under pressure.

The ability to adapt to different landscapes is noteworthy. Corrugated pipes work well in agricultural settings and urban areas. They provide efficient drainage solutions, but not all installations are flawless. Sometimes, decisions made during installation can lead to unexpected outcomes. It's crucial to evaluate the specific needs of each site before proceeding. Understanding their structural characteristics helps in making informed choices.

Corrugated drain pipes are crucial in managing water flow. They can be made from several materials. Each material has unique properties that affect performance.

One common material is polyethylene. It is lightweight yet durable. These pipes resist corrosion well. PVC is another option. It offers strength and flexibility. However, it can crack under extreme temperatures. Concrete pipes are heavier but provide excellent stability. They are often used for larger drainage systems. Metal pipes, like steel, are strong but may rust over time.

Tips: Make sure to consider your project's specific needs. Proper installation is key for performance. Inspect your drainage system regularly. This helps prevent blockages and ensures longevity.

Choosing the right material is not always easy. It requires careful thought and planning. If you rush this step, it might lead to problems later on. Understand the environment where the pipe will be installed. The soil type can greatly affect the pipe's lifespan.

| Material Type | Description | Common Uses | Durability |

|---|---|---|---|

| Polyethylene (HDPE) | High-density polyethylene is flexible, lightweight, and resistant to chemicals. | Residential and commercial drainage systems, stormwater management. | Excellent, with a lifespan exceeding 50 years. |

| Polyvinyl Chloride (PVC) | A strong thermoplastic that is lightweight and affordable. | Agricultural drainage and sewage systems. | Good, typically lasts around 25 to 50 years. |

| Fiberglass | Made from glass fibers, providing high strength and corrosion resistance. | Industrial drainage solutions and chemical transport. | Excellent, with a lifespan of over 30 years. |

| Metal (Steel, Aluminum) | Offers strength and long-lasting durability, though subject to corrosion. | Heavy-duty drainage systems and infrastructure projects. | Moderate, requiring maintenance; lifespan can vary widely. |

Corrugated drain pipes are essential in various drainage systems. These pipes, made of flexible materials, feature a series of grooves. This design helps in channeling water efficiently. They are commonly used in residential and commercial settings for managing surface water.

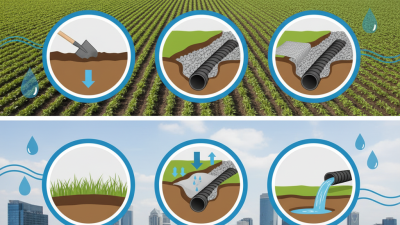

One popular application is in agricultural fields. Farmers use these pipes to direct excess water away from crops. This prevents waterlogging and improves soil health. In urban areas, corrugated pipes are often installed to manage stormwater. They can handle large volumes of water, reducing flooding risks.

Tips: When installing, ensure proper grading. This allows water to flow naturally. Regular maintenance is essential. Check for blockages or damages that could disrupt flow. Remember, the choice of pipe size matters. Too small can lead to overflow issues.

Using corrugated drain pipes in landscaping can prevent soil erosion. They are also effective in drainage basins and retention ponds. However, the installation process can be tricky. It requires a careful assessment of the landscape and soil type. Always consider local regulations and environmental impacts when planning.

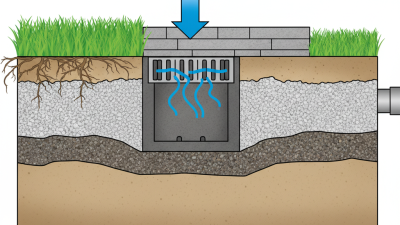

Installing corrugated drain pipes can vary based on the environment. In residential areas, these pipes are often used for yard drainage. They need to be laid at a slight slope to direct water efficiently. Begin by digging a trench that follows this slope. The trench should be deep enough to accommodate the pipe and any gravel you may add. Adding a layer of gravel beneath the pipe helps with water flow.

In agricultural settings, these pipes can handle larger volumes of water. Placing them in fields requires careful consideration of soil type. Sandy soils allow better drainage, while clay soils may not. It's crucial to avoid over-compacting the soil around the pipe. For the best results, cover the pipe with more gravel. This aids in filtering soil particles that could clog the drainage.

Urban environments pose unique challenges. Pipes must navigate around concrete and other infrastructure. Cutting through hard surfaces should be approached cautiously. The installation might not always be perfect, leading to future maintenance issues. It’s essential to check connections to prevent leaks. Reflecting on these elements can significantly impact the functionality of drain systems.

Maintaining corrugated drain pipes is crucial for optimal performance. Regular inspections help identify clogs and damages. Look for signs of wear, such as cracks or rust. If you see any, it might be time for replacement. Remove debris and leaves regularly. This prevents blockages that can lead to flooding.

Cleaning is essential, too. A simple garden hose can often do the trick. For stubborn clogs, consider using a plumber's snake. This tool can clear out debris effectively. Remember, don’t ignore slight issues. A small blockage can quickly escalate. Regular maintenance can extend the lifespan of your drainage system.

Pay attention to the surrounding area as well. If plants grow too close, they may invade the pipes. Roots can cause severe damage over time. Trim back any overgrowth to keep the path clear. Also, assess how water drains in your yard. Puddles can indicate that drainage isn't working as it should. Always stay proactive.