In the world of plumbing and irrigation, Plasson fittings are essential. These fittings are known for their durability and reliability. They help create secure connections in various systems, including water supply and agricultural applications.

Choosing the right Plasson fittings is critical for optimal performance. Factors such as material compatibility and pressure ratings matter. The wrong choice can lead to leaks or system failures, which can be costly. Many users overlook these details, assuming all fittings are created equal.

As we explore the top Plasson fittings for 2026, understanding their features is key. Each type serves a unique purpose, influencing efficiency and longevity. It’s important to consider your specific needs. By doing so, you can avoid mistakes and select the best options for your projects.

Plasson fittings play a crucial role in modern plumbing systems. They are designed to ensure reliable connections between pipes, which is essential for system integrity. These fittings enhance flow efficiency and minimize leaks. Their reputation comes from the durability and robustness they offer in various environments.

Many plumbers rely heavily on these fittings. They provide a secure grip, reducing the risk of disconnection under pressure. However, some installations can be problematic. Improper sizing might lead to weak connections. This requires careful consideration during planning and installation. Finding the right materials is equally important.

Maintenance can be overlooked, leading to issues down the line. Regular inspections can prevent sudden failures. It's vital to remain vigilant and proactive in plumbing practices. Evaluating the performance of these fittings helps ensure a long-lasting system. Turning a blind eye to these details can result in costly repairs.

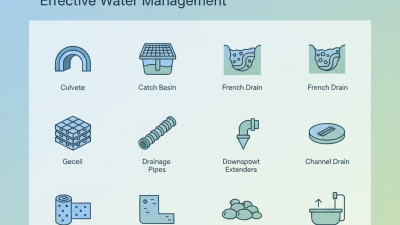

When discussing types of Plasson fittings, it's essential to understand their applications. These fittings are widely used in water supply, irrigation, and drainage systems. They connect various pipes to create a reliable network. Let’s explore some common types.

Compression fittings are popular for their simplicity. They require no extra tools for installation. Push-fit fittings also simplify connections, allowing quick adjustments. Each type has unique features. However, they may not be ideal for every scenario. Selecting the wrong fitting can lead to leaks.

Tips for choosing the right fitting include considering the pipe size and material. Ensure compatibility to avoid issues later. Always check for any visible wear. This can indicate a need for replacement. Sometimes, people overlook this detail.

Don’t forget to evaluate the operational environment. Features such as temperature and pressure can affect performance. An unsuitable fitting could cause failure under stress. Evaluate your needs and research thoroughly. This groundwork can prevent costly mistakes.

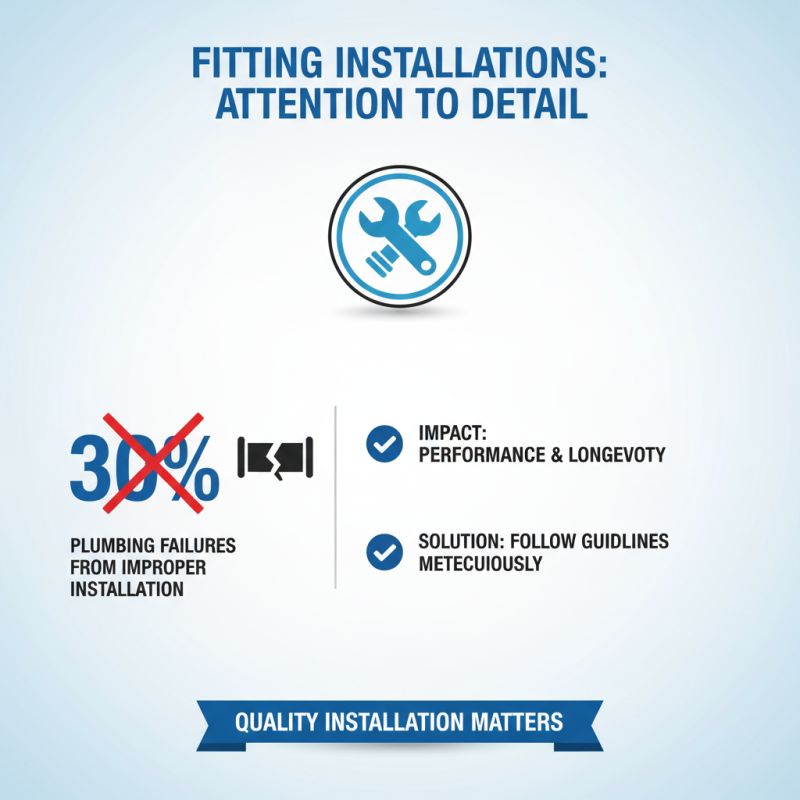

When working with fitting installations, attention to detail is crucial. Proper installation can significantly impact overall performance and longevity. Research indicates that nearly 30% of plumbing failures stem from improper fittings installation. This statistic highlights the importance of following guidelines meticulously.

Begin by preparing the workspace. Ensure all tools are clean and functional. Measure the fittings accurately. Misalignment can lead to leaks or system failures. According to industry standards, maintaining a gap of approximately 10% during installation can accommodate temperature changes. This precaution helps prevent material stress.

Use the appropriate sealant for your specific materials. A common mistake is to overlook sealant requirements, leading to leaks. Professionals recommend allowing adequate curing time based on the manufacturer's guidelines. Too often, installations are rushed, resulting in premature failures. Understanding these guidelines can help overcome potential challenges. Aim for precision and patience during fittings installation.

Plasson fittings are widely used across various industries, showcasing their versatility and reliability. These fittings excel in water supply systems, agricultural irrigation, and industrial applications. According to industry reports, the use of plastic fittings, such as those made from polyethylene, is expected to grow by 5% annually. This growth reflects the increasing need for efficient and sustainable solutions.

In agriculture, Plasson fittings contribute significantly to irrigation systems. They help optimize water usage, supporting efficient farming practices. A recent survey revealed that farmers using modern irrigation fittings reported a 20% increase in yields. However, not all applications have been successful. Some users have faced issues with improper installation, leading to leaks and reduced efficiency. This highlights the importance of training for installation teams.

In industrial settings, Plasson fittings are integrated into diverse processes, from chemical transportation to wastewater management. Their resistance to corrosion and pressure makes them suitable for demanding environments. Nevertheless, challenges remain. For instance, industries often face compatibility issues with various fluids. This can lead to unexpected failures if not properly addressed. Continuous innovation is crucial to tackle such issues and improve reliability.

Maintaining Plasson fittings is crucial for their longevity. Regular inspections can reveal early signs of wear. According to industry reports, proper maintenance can extend the lifespan of these fittings by up to 30%. Many users overlook small leaks or cracks. Ignoring these issues often leads to bigger problems down the line.

Cleaning is essential for efficiency. Dirt and debris can hinder performance. Reports show that fittings with clogged connections may reduce flow rates by 20%. Users should ensure fittings are free from corrosive substances. An occasional gentle wash can make a big difference. Some might rush this step, undermining its importance.

Lubrication is another key factor. A well-lubricated fitting operates smoothly and resists wear. Data suggests that fitting joints lose efficiency without proper lubrication. However, too much lubricant can attract grime and dust. Users should find a balance that works for their specific conditions. Regular checks can help identify if adjustments are needed. Each fitting has its unique requirements, which can be challenging to navigate. Adjusting to these needs is essential for prolonged performance.

This chart illustrates the relationship between regular maintenance frequency and the longevity of Plasson fittings. Maintaining fittings regularly can significantly extend their lifespan.